MULTIFUNCTIONAL

AUTO AND TECHNICAL CENTRES

IN CESIS AND VALMIERA

DEVELOPMENT, MANUFACTURING

AND CAR SERVICING

FOR INDUSTRIAL CLIENTS

The modern production unit of “AK12” METALWORKING AND MECHANICAL ENGINEERING CENTER in Cesis offers a complete cycle of production of industrial machinery, non-standard equipment and machinery; placement of metalworking services; custom manufacture of agricultural, forestry and industrial machinery spare parts.

The quality label of “AK12” is a strong team of engineers and craftsmen with many years of experience working with industrial machinery, so we can offer design, manufacture and assembly of vehicle equipment projects. Our craftsmen will install the necessary additional equipment, adapting it to the existing equipment. We install a variety of units, their mounting plates, hydraulic systems and their electronic control systems, hydraulic manipulators and equipment, cargo boxes and other special equipment that we can supply, manufacture or customize in our new truck and specialty truck metalworking and mechanical engineering plant in Cesis. We also design and manufacture various types of industrial containers and accessories for agricultural, utility, road construction and industrial manufacturing companies.

Utility, agricultural and forestry equipment solutions

“AK12” offers the design, manufacture and assembly of vehicle equipment projects for urban utilities, agro-industry and forestry. Our craftsmen will install the necessary additional equipment, adapting it to existing equipment or vehicles, including a wide variety of tractor equipment. We install various units, their mounting plates, hydraulic systems and their electronic control systems, hydraulic manipulators and equipment, cargo boxes and other special equipment, which we can supply, make or customize in our machines in Cesis.

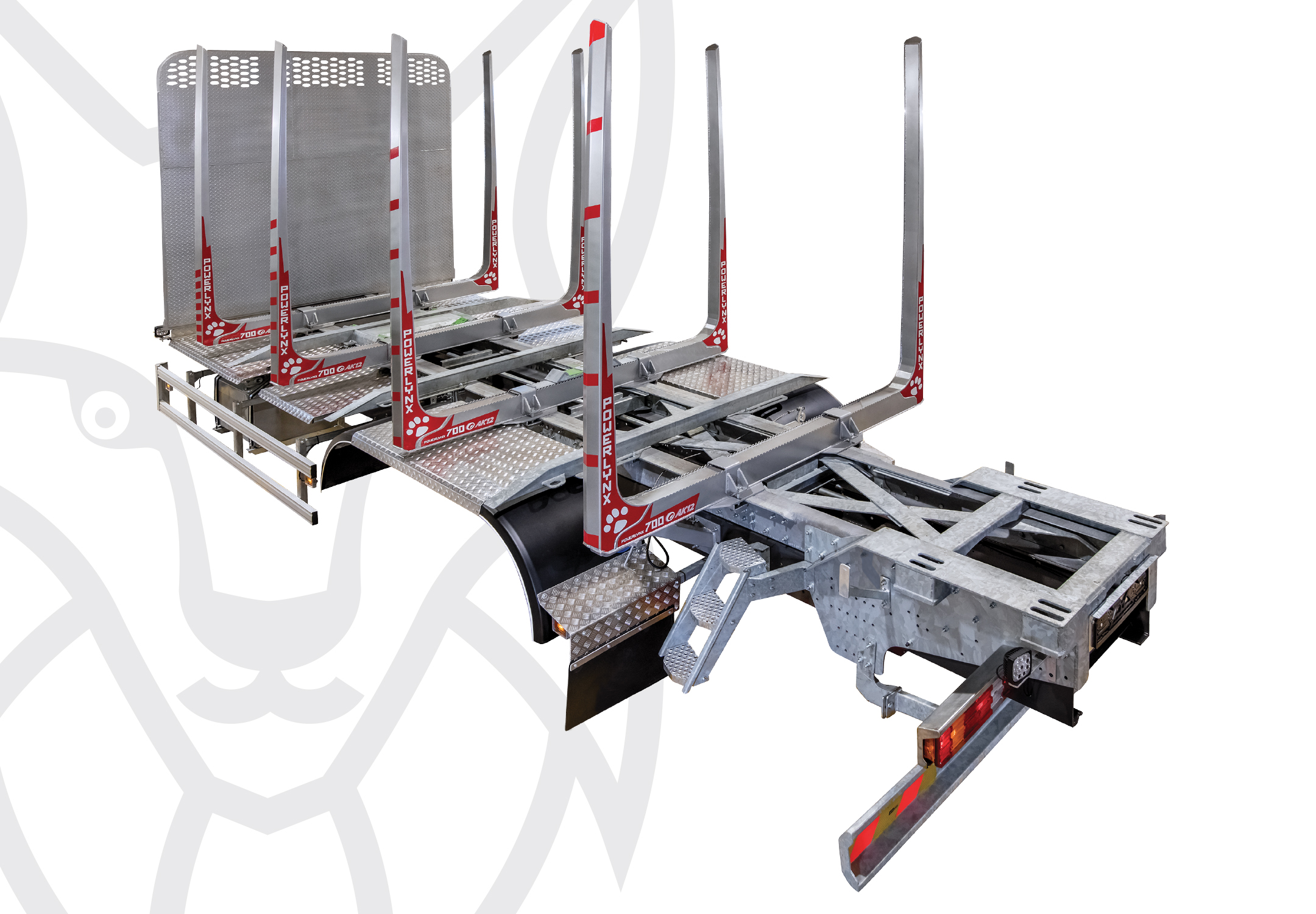

MACHINERY WITH THE BRAND POWERLYNX

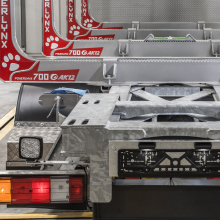

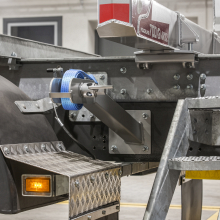

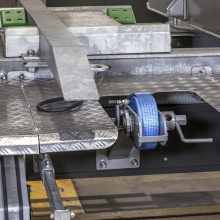

Superstructures for timber trucks POWERLYNX – sustainable investment. At its manufacturing unit, located in Cēsis, Latvia, the LLC (SIA) “AK12” manufactures and assembles various forestry machinery transport units, including superstructures for trucks and trailers, components and aggregates – subframes, bunks, load tighteners, headboards, under-run protection barriers, crane brackets and boom supports, hydraulic manipulator bases, additional frame fasteners and many other elements required for successful transportation of wood.

Fully equipped timber truck superstructures manufactured by “AK12” have been marked with the brand POWERLYNX – translated as “lynx of power”, a specie widespread in forests of Nordic countries, which impersonates both power and agility. Each POWERLYNX superstructure set is custom-manufactured and conforms to the customer’s requirements, as well as the truck to be equipped.

POWERLYNX superstructures are suitable for all the most common truck models traditionally used for transportation of round timber and logging works. Majority of components are original products, developed by the “AK12” engineers over a lengthy period and are especially suitable for the specifics of logging works and logistics in the Baltic States. The company provides full warranty and post-warranty service of POWERLYNX superstructures and additionally installed equipment at the specialised service centres in Cēsis and Valmiera, as well as at cooperating companies in other regions of Latvia.

POWERLYNX products mainly are made of high quality steel, which provides several advantages compared to other metals traditionally used for manufacture of bodies for timber trucks. Application of steel is economically justified due to its durability, mechanical properties, processing and repair options. In order to protect POWERLYNX products from the environmental exposure, their key parts are hot-dip galvanised, and separate components are coated with at least double-layer of epoxy and polyurethane protective painting in accordance with the RAL colour palette at the customer's choice. Before coating, all parts of the body are shot blasted.

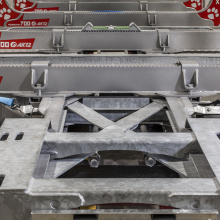

POWERLYNX SUBFRAMES

Subframe is structural construction of a timber truck and therefore adjusted to the technical parameters of any truck model or modification at the stage of construction and manufacture. Subframes are manufactured using 8 mm C-profile special steel, which is resistant to fluctuations in ambient temperature from -40°C to +50°C. Especially flexible steel is used, thus making the body resistant to vibrations and torsion, and ensuring its durability in especially severe operating conditions, for example, when fully loaded timber truck is exploited on poor quality forest roads. Double X-shape fasteners increase torsion resistance of the subframe and truck chassis and contributes to stability. All the fasteners are hot-dip galvanised. Different assembly of hydraulic manipulator (loader) is available – on hydraulic extendible or fixed bracket.

POWERLYNX HEADBOARDS

POWERLYNX headboards are made of durable steel frame and may be equipped either with coating made of anodized riffled aluminium sheets or painted riffled steel sheets, or steel wire mesh. Steel sheets are the most common solution. Headboards are of especially robust constructions, which are able to resist both severe operating conditions and impacts caused by the timber to be transported in the long term, and may be additionally equipped by broom, crowbar and spade holders, as well as additional LED lights.

POWERLYNX TIMBER BUNKS

POWERLYNX timber bunks are original products of “AK12”, made of high quality and resistance steel STRENX 650MC or STRENX 700MC. Bunks are easy to assemble, resistant, light, safe and intended for usage under extreme weather conditions, and these are among the lightest and most resistant steel timber bunks currently available in the market. Innovative design with a special aerodynamic stake profile increases its physical resistance against the load, allows loading more timber, thus helping to reduce specific fuel consumption when driving on a highway at a higher speed. Aerodynamic steel profile stakes are available both with corrugated and smooth bottom edge of bunk, as well as there are economy-class timber bunks made of rectangle profile pipes. We offer custom-made stainless steel timber bunks. Service life of POWERLYNX stainless steel bunks exceeds 10 years.

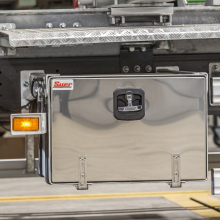

POWERLYNX BODY ACCESSORIES

• Hydraulic system oil tanks;

• Lockable boxes for tools and accessories

(aluminium or plastic);

• Platform-located boxes for flexible hydraulic pipes;

• Platform safety barriers and their fasteners;

• Wheel mudguards;

• Fuel tank and hydraulic system oil tank guards, toolbox guards,

air receiver guards (made of aluminium);

• Rear body safety construction;

• Under-run protection construction;

• Original ladder;

• Gripper bucket supports;

• Hydraulic manipulator boom supports;

• Front and rear LED working lamps;

• Additional LED working lamps at headboard;

• Broom, crowbar and spade holders;

• Snow-chain holders;

• Additional rubber pads for hydraulic manipulator support legs;

... and many other products according to demand of the customers.

POWERLYNX superstructures have 2-year manufacturer's warranty. Planned average service life – 7 years. Manufacturing process of POWERLYNX products is subjected to constant creation and introduction of constructive improvements and tests of applicable materials.

WE MANUFACTURE, INSTALL AND PROVIDE SERVICE DURING THE WARRANTY AND POST-WARRANTY PERIOD

1 Superstructures for timber trucks POWERLYNX;

2 Bunks for timber trucks POWERLYNX;

3 Galvanized safety barriers for timber trucks;

4 Pads for hydraulic manipulator supports;

5 Garbage containers;

6 Debris containers;

7 Loader forks;

8 Frontal and other loader buckets;

9 Superstructures for garbage trucks (only installation and repairs);

10 Sand spreaders and other road construction machinery;

11 Spare parts for chip crushers;

12 Manufacture of hydraulic cylinders;

13 Manufacture of containers for chips, garbage, ashes and drying;

14 Maintenance and overhaul of loaders LOGLIFT, HIAB, KESLA etc.;

15 Off-site service with specially equipped Mobile service truck.

Diagnostics using BOSCH and WABCO WURTH equipment, maintenance using MOBIL and EUROL oils and lubricants. Welding, including Al TIG, MIG, MMA. Repair of hydraulic cylinders, including manufacture of new, custom-made cylinders.

WE WORK TO MAKE YOU MACHINERY WORK!

Price lists